How Are Aluminum Windows Made?

Aluminum windows are a favorite for modern homes and buildings because they are strong, lightweight, and energy-efficient. But how exactly are they made? The process involves several important steps, using advanced machines and skilled craftsmanship. Let’s break it down in simple terms.

1. Why Aluminum is Used for Windows

Aluminum is the perfect material for windows because it has many great qualities:

- Strong and Long-Lasting: It resists rust and doesn’t break easily.

- Energy Efficient: Special designs help keep heat in during winter and out during summer.

- Eco-Friendly: Aluminum is recyclable, making it good for the environment.

This makes aluminum a top choice for making windows that look good and work well.

2. From Raw Material to Aluminum

The journey starts with bauxite, a type of rock rich in aluminum. The process is as follows:

- Mining and Refining: Bauxite is mined and turned into alumina, a white powder.

- Smelting: Using electricity, alumina is melted into pure aluminum.

- Mixing with Other Metals: Aluminum is combined with small amounts of other metals to make it stronger.

Once this is done, the aluminum can be shaped into window frames.

3. Shaping the Frames: Aluminum Extrusion

Extrusion is how aluminum is shaped into long strips to make window frames. Here’s how it works:

- Heating: Aluminum is heated until it’s soft.

- Shaping: The soft aluminum is pushed through a mold (called a die) to create the desired shape.

- Cutting: These long shapes are cut into smaller pieces for the windows.

This step ensures the frames are the right size and shape to fit the glass and other parts.

4. Protecting and Coloring the Frames

The aluminum frames are treated to look better and last longer. There are a few common methods:

- Anodizing: Adds a protective layer to prevent rust.

- Powder Coating: A strong, colorful coating is baked onto the surface.

- Painting: Frames are painted to match different styles and colors.

These treatments make the frames look stylish and durable for years to come.

5. Cutting and Adding Holes for Parts

Before putting the frames together, they are cut and drilled for screws, locks, and handles. Machines are used to:

- Cut the aluminum into the exact size needed.

- Drill holes for hinges and handles.

- Smooth out any rough edges so they’re safe to handle.

This step makes sure the frames are ready for assembly.

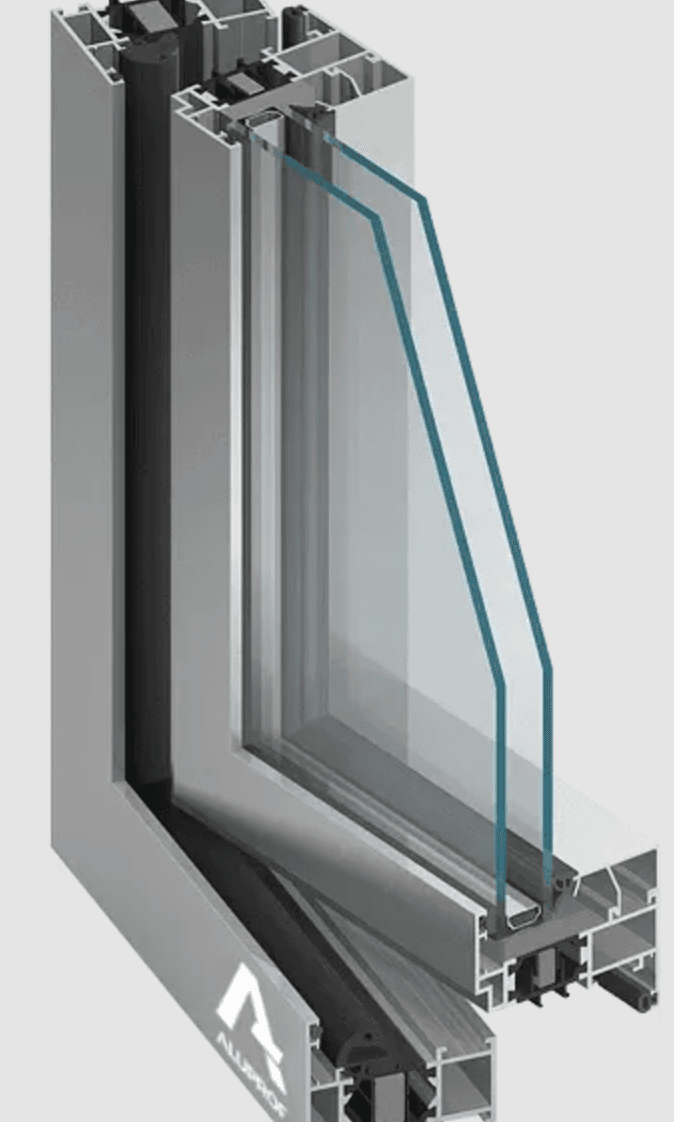

6. Adding Thermal Breaks for Energy Efficiency

Modern aluminum windows include thermal breaks, which help block heat or cold from passing through the frames. This works like insulation in walls:

- Plastic Strips: A strip of plastic is placed inside the frame to separate the inside from the outside.

- Better Insulation: This keeps homes warmer in winter and cooler in summer.

Thermal breaks make aluminum windows energy-efficient, which saves money on energy bills.

7. Preparing the Glass

The glass is just as important as the frame. Manufacturers use special glass, such as:

- Double or Triple Glazing: Two or three layers of glass with air or gas between them.

- Low-E Coatings: A special layer on the glass that reflects heat.

- Safety Glass: Strong glass that doesn’t shatter easily.

The glass is cut and sealed to fit perfectly inside the aluminum frame.

8. Putting the Window Together

This is where all the pieces come together:

- Assembling Frames: Corners are joined and fastened securely.

- Inserting Glass: The glass is placed inside the frame and sealed.

- Adding Hardware: Handles, locks, and hinges are attached.

After this step, the aluminum windows are fully assembled and ready to be tested.

9. Testing for Quality

Before selling the windows, manufacturers run tests to ensure they work well and are safe. These tests check:

- Water and Air Leaks: Making sure no rain or wind gets inside.

- Strength: Ensuring the windows can handle pressure.

- Energy Efficiency: Confirming the windows keep heat or cold in or out as designed.

Only windows that pass all the tests are sent out for sale.

10. Delivery and Installation

Once the windows are ready, they are shipped to homes and building sites. Professional installers:

- Fit the frames securely in the walls.

- Seal the windows to prevent air or water leaks.

- Check that they open and close smoothly.

With proper installation, aluminum windows can last for many years.

Conclusion

The process of making aluminum windows is a mix of science, engineering, and creativity. Each step from mining aluminum to installing the final product is important to ensure the windows are strong, energy-efficient, and visually appealing. Now, every time you look through an aluminum window, you’ll know the effort that went into making it.

FAQs

1. Why are aluminum windows better than other types?

They are lightweight, strong, long-lasting, and energy-efficient.

2. Can aluminum windows be recycled?

Yes, aluminum is 100% recyclable, making it eco-friendly.

3. How do thermal breaks improve aluminum windows?

They prevent heat from passing through the frame, making the windows more energy-efficient.

4. Are aluminum windows expensive?

While they can be more expensive than other types, their durability and low maintenance make them a good investment.

5. How long do aluminum windows last?

With proper care, they can last 20-30 years or more.

Мore about aluminum windows on the website https://elwido.com/